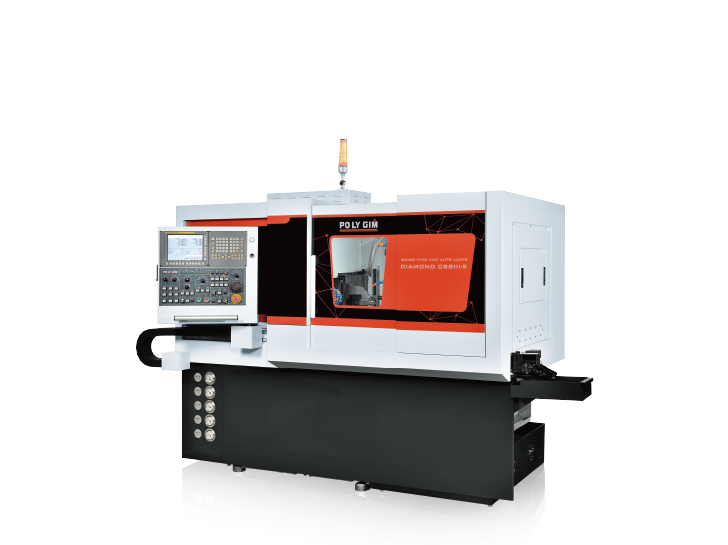

Diamond CSB III-S

Swiss Type CNC Lathe

cnc swiss precision machining

Diamond CSB III-SUpgrade your production with our CNC Swiss Precision Machining centers. Designed for high-precision and efficiency, these machines excel in producing complex parts with tight tolerances. Multi-axis capabilities allow for faster cycle times, making them ideal for industries requiring both precision and speed. Durable and user-friendly, our centers offer a robust, long-term manufacturing solution.

CNC Swiss Precision Machining(CSBIII-S) Structure

1

O.D. Turning Tool

O.D. Turning Tool

2

I.D. Stationary Tool Holder

I.D. Stationary Tool Holder

3

Cross Working Driven Tool(unremovable)

Cross Working Driven Tool(unremovable)

4

Std:4 pcs Back I.D Stationary Tool Holder

Opt:4 pcs Back Working Driven Tool Holder

Std:4 pcs Back I.D Stationary Tool Holder

Opt:4 pcs Back Working Driven Tool Holder

Opt:Sub-spindle has Y2 axis

5 Three pieces of cross driven tool holder(removable), eight pieces optional tool holders listed as below:

Saw Blade Seat

Speed Ratio: 1:0.5806

Max. (rpm): 4000RPM

Saw Blade Aperture: 12.7

Max. Diameter of Saw Blade: 50

Polygon Milling Tool Holder

Speed Ratio: 1:0.6

Max. (rpm): 4000RPM

Shaft Diameter: 13

Max. Diameter of Blade: 70

Thread Whirling Device (import)

Speed Ratio: 1:1

Max. (rpm): 6000RPM

Angle adjustment range: 20

Max. machining size: 11.4

Thread Whirling Device (Domestic)

Speed Ratio: 1:0.896

Max. (rpm): 6000RPM

Angle adjustment range: 15

Max. machining size: 10.5

Cross Driving Tool Holder

Speed Ratio: 1:1

Max. (rpm): 8000RPM

Collet: ER16M

2 pcs 360° Rotary Driven Tool Holder

Speed Ratio: 1:1

Max. (rpm): 6000RPM

Angle adjustment range: 360

Collet: ER11-AC

3 pcs 360° Rotary Driven Tool Holder

Speed Ratio: 1:1

Max. (rpm): 6000RPM

Collet: ER16

6 pcs 360° Rotary Driven Tool Holder

Speed Ratio: 1:1

Max. (rpm): 6000RPM

Collet: ER16/ER11

Standard Accessories:

Controller: Fanuc 0I-TF PLUS

Controller: Fanuc 0I-TF PLUS Main Spindle

Main Spindle Back Spindle

Back Spindle Working Light

Working Light Coolant System

Coolant System Part off Detection Sensor

Part off Detection Sensor Part Catcher

Part Catcher

Live Bushing

Live Bushing Fixed Bushing (Except 25B III / 25CSB III)

Fixed Bushing (Except 25B III / 25CSB III) 6 pcs O.D. Turning Tool Holder

6 pcs O.D. Turning Tool Holder 4 pcs I.D. Stationary Tool Holder

4 pcs I.D. Stationary Tool Holder 4 pcs Back I.D. Stationary Tool Holder

4 pcs Back I.D. Stationary Tool Holder 4 pcs Back I.D. Stationary Tool Holder

4 pcs Back I.D. Stationary Tool Holder 2 pcs+3 pcs Cross Working Driven Tool Holder

2 pcs+3 pcs Cross Working Driven Tool Holder

Optional Accessories:

Controller: Fanuc 31i-B or Mitsubishi M80

Controller: Fanuc 31i-B or Mitsubishi M80 CS Axis (0.001° Orientation)

CS Axis (0.001° Orientation) Chip Conveyor + Bucket

Chip Conveyor + Bucket

4 pcs Back Working Driven Tool Holder

4 pcs Back Working Driven Tool Holder

(If choose Y2 axis need to option) Y2 axis

Y2 axis 2 pcs Front I.D. Stationary Tool Holder

2 pcs Front I.D. Stationary Tool Holder

(sub-spindle with belt type motor)

CNC Swiss Precision Machining Video

CSB III-S (Whirling)

Machine Specifications:

| Model | DIAMOND 12 CSB III-S | |

|---|---|---|

| Working Range | Max. Machining Dia | Ø12.7 mm |

| Max. Machining Length Per Chucking |

200 mm | |

| Max. Drilling Dia. (Main Spindle) | Ø7 mm | |

| Max. Drilling Dia. (Sub Spindle) | Ø7 mm | |

| Max. Tapping Dia. (Main Spindle) | M6 | |

| Max. Tapping Dia. (Sub Spindle) | M6 | |

| O.D. Tooling | Number of Tools | 6 |

| Dimension | □12 ×12 × 120 | |

| I.D. Tooling | Number of Tools | 4 |

| Dimension | 10 mm (ER16) | |

| Cross Working Driven Tooling | Number of Tools | 2+3 |

| Dimension | 10 mm (ER16) | |

| Speed | 200~6,000rpm | |

| Back I.D. Tooling | Number of Tools | 4 + 4 |

| Dimension | 10 mm (ER16) | |

| Back Working Driven Tooling (Option) | Number of Tools | 4 |

| Dimension | 10mm (ER16) | |

| Speed | 5,000rpm | |

| Spindle | Spindle Hole Dia. | ø13 mm |

| Spindle Speed | 200~12,000rpm | |

| Main Spindle Indexing Angle | C-axis | |

| Back Spindle | Spindle Hole Dia. | ø13 mm |

| Spindle Speed | 200~6,000 rpm | |

| (Option built-in motor) | 200~12,000rpm | |

| Max. Length for Front Ejection | 50 mm | |

| Sub Spindle Indexing Angle | C-axis | |

| Rapid Traverse | X1, Y1, Z1, X2, Z2 | 30 m / min |

| Motor | Built-in Spindle Motor | 1.5 / 2.2 kW |

| Back Spindle Motor | 1.1 / 3.7 kW | |

| (Option built-in motor) | 1.5 / 2.2 kW | |

| Y1, Z1, X2, Z2 Axes Motor | 1 kW | |

| X1 Axis Motor | 1.6 kW | |

| Y2 Axis Motor (Option) | 1.6 kW | |

| Coolant Pump Motor | 1 HP | |

| Lubrication Motor | 4 w | |

| Cross Driven Tool Motor | 2.2 kW | |

| Back Driven Tool Motor (Option) |

1 kW | |

| Y2 Axis with Back Driven Tool Motor (Option) |

2.2 kW | |

| Center Height | 890 mm | |

| Machine Dimensions | Weight | 2,020 kg |

| (Option Y2 Axis) | 2,400 kg | |

| Machine Dimensions | 2,440 x 1,430 x 1,650 mm | |

| (Option Y2 Axis) | 2,690 x 1,495 x 1,890 mm | |

| Air | Air Pressure | 5 kg / cm |

| Air Supply | 10 L / min | |

| Model | DIAMOND 16 CSB III-S | |

|---|---|---|

| Working Range | Max. Machining Dia | Ø16.5 mm |

| Max. Machining Length Per Chucking |

200 mm | |

| Max. Drilling Dia. (Main Spindle) | Ø10 mm | |

| Max. Drilling Dia. (Sub Spindle) | Ø7 mm | |

| Max. Tapping Dia. (Main Spindle) | M8 | |

| Max. Tapping Dia. (Sub Spindle) | M6 | |

| O.D. Tooling | Number of Tools | 6 |

| Dimension | □12 ×12 × 120 | |

| I.D. Tooling | Number of Tools | 4 |

| Dimension | 10 mm (ER16) | |

| Cross Working Driven Tooling | Number of Tools | 2+3 |

| Dimension | 10 mm (ER16) | |

| Speed | 200~6,000rpm | |

| Back I.D. Tooling | Number of Tools | 4 + 4 |

| Dimension | 10 mm (ER16) | |

| Back Working Driven Tooling (Option) | Number of Tools | 4 |

| Dimension | 10mm (ER16) | |

| Speed | 5,000rpm | |

| Spindle | Spindle Hole Dia. | ø17 mm |

| Spindle Speed | 200~10,000rpm | |

| Main Spindle Indexing Angle | C-axis | |

| Back Spindle | Spindle Hole Dia. | ø17 mm |

| Spindle Speed | 200~6,000 rpm | |

| (Option built-in motor) | 200~10,000rpm | |

| Max. Length for Front Ejection | 50 mm | |

| Sub Spindle Indexing Angle | C-axis | |

| Rapid Traverse | X1, Y1, Z1, X2, Z2 | 30 m / min |

| Motor | Built-in Spindle Motor | 1.5 / 2.2 kW |

| Back Spindle Motor | 1.1 / 3.7 kW | |

| (Option built-in motor) | 1.5 / 2.2 kW | |

| Y1, Z1, X2, Z2 Axes Motor | 1 kW | |

| X1 Axis Motor | 1.6 kW | |

| Y2 Axis Motor (Option) | 1.6 kW | |

| Coolant Pump Motor | 1 HP | |

| Lubrication Motor | 4 w | |

| Cross Driven Tool Motor | 2.2 kW | |

| Back Driven Tool Motor (Option) |

1 kW | |

| Y2 Axis with Back Driven Tool Motor (Option) |

2.2 kW | |

| Center Height | 890 mm | |

| Machine Dimensions | Weight | 2,170 kg |

| (Option Y2 Axis) | 2,550 kg | |

| Machine Dimensions | 2,440 x 1,430 x 1,650 mm | |

| (Option Y2 Axis) | 2,690 x 1,495 x 1,890 mm | |

| Air | Air Pressure | 5 kg / cm |

| Air Supply | 10 L / min | |

| Model | DIAMOND 20 CSB III-S | |

|---|---|---|

| Working Range | Max. Machining Dia | Ø20 mm |

| Max. Machining Length Per Chucking |

200 mm | |

| Max. Drilling Dia. (Main Spindle) | Ø10 mm | |

| Max. Drilling Dia. (Sub Spindle) | Ø7 mm | |

| Max. Tapping Dia. (Main Spindle) | M8 | |

| Max. Tapping Dia. (Sub Spindle) | M6 | |

| O.D. Tooling | Number of Tools | 6 |

| Dimension | □12 ×12 × 120 | |

| I.D. Tooling | Number of Tools | 4 |

| Dimension | 10 mm (ER16) | |

| Cross Working Driven Tooling | Number of Tools | 2+3 |

| Dimension | 10 mm (ER16) | |

| Speed | 200~6,000rpm | |

| Back I.D. Tooling | Number of Tools | 4 + 4 |

| Dimension | 10 mm (ER16) | |

| Back Working Driven Tooling (Option) | Number of Tools | 4 |

| Dimension | 10mm (ER16) | |

| Speed | 5,000rpm | |

| Spindle | Spindle Hole Dia. | ø22 mm |

| Spindle Speed | 200~10,000rpm | |

| Main Spindle Indexing Angle | C-axis | |

| Back Spindle | Spindle Hole Dia. | ø22 mm |

| Spindle Speed | 200~6,000 rpm | |

| (Option built-in motor) | 200~10,000rpm | |

| Max. Length for Front Ejection | 50 mm | |

| Sub Spindle Indexing Angle | C-axis | |

| Rapid Traverse | X1, Y1, Z1, X2, Z2 | 30 m / min |

| Motor | Built-in Spindle Motor | 2.2 / 5.5 kW |

| Back Spindle Motor | 1.1 / 3.7 kW | |

| (Option built-in motor) | 2.2 / 5.5 kW | |

| Y1, Z1, X2, Z2 Axes Motor | 1 kW | |

| X1 Axis Motor | 1.6 kW | |

| Y2 Axis Motor (Option) | 1.6 kW | |

| Coolant Pump Motor | 1 HP | |

| Lubrication Motor | 4 w | |

| Cross Driven Tool Motor | 2.2 kW | |

| Back Driven Tool Motor (Option) |

1 kW | |

| Y2 Axis with Back Driven Tool Motor (Option) |

2.2 kW | |

| Center Height | 890 mm | |

| Machine Dimensions | Weight | 2,220 kg |

| (Option Y2 Axis) | 2,600 kg | |

| Machine Dimensions | 2,440 x 1,430 x 1,650 mm | |

| (Option Y2 Axis) | 2,690 x 1,495 x 1,890 mm | |

| Air | Air Pressure | 5 kg / cm |

| Air Supply | 10 L / min | |

| Model | DIAMOND 25 CSB III-S | |

|---|---|---|

| Working Range | Max. Machining Dia | Ø26 mm |

| Max. Machining Length Per Chucking |

200 mm | |

| Max. Drilling Dia. (Main Spindle) | Ø10 mm | |

| Max. Drilling Dia. (Sub Spindle) | Ø7 mm | |

| Max. Tapping Dia. (Main Spindle) | M8 | |

| Max. Tapping Dia. (Sub Spindle) | M6 | |

| O.D. Tooling | Number of Tools | 6 |

| Dimension | □12×12 × 120 | |

| I.D. Tooling | Number of Tools | 4 |

| Dimension | 10 mm (ER16) | |

| Cross Working Driven Tooling | Number of Tools | 2+3 |

| Dimension | 10 mm (ER16) | |

| Speed | 200~6,000rpm | |

| Back I.D. Tooling | Number of Tools | 4 + 4 |

| Dimension | 10 mm (ER16) | |

| Back Working Driven Tooling (Option) | Number of Tools | 4 |

| Dimension | 10mm (ER16) | |

| Speed | 5,000rpm | |

| Spindle | Spindle Hole Dia. | ø27 mm |

| Spindle Speed | 200~8,000rpm | |

| Main Spindle Indexing Angle | C-axis | |

| Back Spindle | Spindle Hole Dia. | ø27 mm |

| Spindle Speed | 200~6,000 rpm | |

| (Option built-in motor) | 200~8,000rpm | |

| Max. Length for Front Ejection | 50 mm | |

| Sub Spindle Indexing Angle | C-axis | |

| Rapid Traverse | X1, Y1, Z1, X2, Z2 | 30 m / min |

| Motor | Built-in Spindle Motor | 2.2 / 5.5 kW |

| Back Spindle Motor | 1.1 / 3.7 kW | |

| (Option built-in motor) | 2.2 / 5.5 kW | |

| Y1, Z1, X2, Z2 Axes Motor | 1 kW | |

| X1 Axis Motor | 1.6 kW | |

| Y2 Axis Motor (Option) | 1.6 kW | |

| Coolant Pump Motor | 1 HP | |

| Lubrication Motor | 4 w | |

| Cross Driven Tool Motor | 2.2 kW | |

| Back Driven Tool Motor (Option) |

1 kW | |

| Y2 Axis with Back Driven Tool Motor (Option) |

2.2 kW | |

| Center Height | 890 mm | |

| Machine Dimensions | Weight | 2,270 kg |

| (Option Y2 Axis) | 2,650 kg | |

| Machine Dimensions | 2,440 x 1,430 x 1,650 mm | |

| (Option Y2 Axis) | 2,690 x 1,495 x 1,890 mm | |

| Air | Air Pressure | 5 kg / cm |

| Air Supply | 10 L / min | |

Inquiry